This article will help you if you have ever tried to build a table but felt intimidated by the thought of using wood. This article will help you build a solid-wood table top. It will cover Cross-grain, mortise, tenon, rounding edges, choosing a material, and mortise, tenon, joints. How to measure the top's dimensions will be covered.

Cross-grain sanding

A solid wood table top can be smoothed by a cross-grain sanding operation. However, the process is not without risks. Dust from the table can have an adverse effect on your air quality so make sure you work in a well-ventilated place. It is important to plan enough time for each stage. The first step of the sanding procedure is to remove existing finishes. This step is the most tedious and can have a significant impact on the final look.

Before sanding the wood, be sure to examine it carefully. Professionals can get away with taking shortcuts, but a novice needs to be aware of possible mistakes and avoid making them. This article will provide you with useful tips to ensure that you achieve the look and finish you're after. A flat block is best when backing sandpaper on a solid wood tabletop. It can lead to hollowing of the wood grain if you don't have a backing block made from sandpaper.

Mortise joints and tenon joints

Mortise and Tenon joints are two of the most versatile types woodworking joints. These joints are common in tabletop projects. There are however some differences. Some cases will require glue, while others may require a tight fit. A solid wood table top must fit snugly together. Here are a few things to look for when choosing this type of woodworking joint.

The tenon should not be more than a third of the material's thickness. If your table top measures 3/4" thick, you will need a 1/4" tenon. For the apron, you can use the same principle. Before the tenon can be fitted, it is necessary to cut the top shoulders and bottom shoulders of each piece. Also, mark the tenoning marks on both sides of each board to determine the exact depth of your joint.

Rounding edges

Rounding the edges is an important step to give your table a beautiful look. Wood expands and contracts twice the amount along its grain. Rounding your table's edges will allow it to naturally swell and contract, increasing beauty and value. You can choose from a finished or unfinished table made of solid wood. Before you buy one, make sure you check the recommended size for the table top/base.

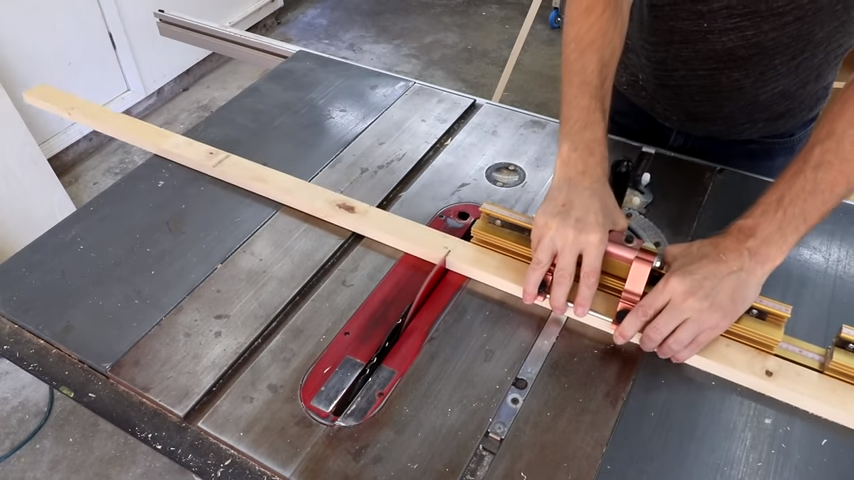

Before you attach the edging around your table top, fit the eight pieces from end to end. Take a testboard and measure the angle between straight molding ends, the tabletop edge, and adjust as necessary. If you're using a table saw, run the straight pieces through the router first to ensure that they fit perfectly. After cutting the tabletop, glue the edges and sand them to ensure that they are flush with the top.

The choice of a tabletop surface

Solid wood is a durable material for table tops. MDF material is closest to a solid wood tabletop. While solid wood tabletops can withstand moisture well, the smallest crack can quickly become a breeding area for fungi. Solid wood also loses its structural integrity when subjected to extreme changes in humidity or temperature. It is important to consider how the table will be maintained if it is being used in a dining or kitchen area.

Oak: Oak, although a beautiful hardwood, is expensive and requires a longer growing period than other hardwoods. Oak table tops can last a lifetime if properly maintained, and the grain is often rich and varied. You can match the colour of your furniture or add stains to highlight the oak grain. The surface can be stained easily, so make sure you protect it from the sun.

FAQ

How often do I need to buy new supplies

You may have to replace certain tools. You'll need to sharpen your hand tools regularly if you use them. You'll also need to replace parts if you use power tools. Avoid buying too many products at once. Spread your purchases out over several months.

What is the difference in plywood and particleboard?

Plywood consists of layers made from wood and pressed together by pressure. Plywood can be cut to different thicknesses. It's commonly used as flooring and cabinets. Particle board consists of sawdust mixed and resin. The resin is then compressed into large blocks. It's commonly used for home improvement projects. Both types are sturdy and easy to cut.

What time does it take for furniture to be finished?

It depends on the size and condition of the furniture. Smaller projects like boxes and picture frames can be finished within one day. Larger projects like tables and desks take many days. It takes time for the wood to be stained and sealed properly.

What tools should I start with when becoming a woodworker?

Woodworking is an art form that requires patience and practice. It takes time and practice to master the various techniques and tools required for woodworking.

There are many woodworking tools on the current market. Some people prefer using power tools while others prefer hand tools.

While you have the option to pick what you like, it is essential that you get the right tool for the job. If you don't have any experience, you may consider starting with a basic set of hand tools.

You might also want to learn how a router works, which allows you to cut wood into intricate shapes. These tools can be purchased at most hardware stores.

What's the difference between a hobbyist and a professional woodworker?

Hobbyists are passionate about making things from wood, while professionals tend to be more focused on the quality and craftsmanship of their work. Hobbyists tend to take pride and share their creations with family and friends. Professionals will spend hours researching designs before they begin working on a project. They'll be meticulous about every aspect of their work, from choosing the best materials to finishing it perfectly.

Statistics

- Overall employment of woodworkers is projected to grow 8 percent from 2020 to 2030, about as fast as the average for all occupations. (bls.gov)

- The U.S. Bureau of Labor Statistics (BLS) estimates that the number of jobs for woodworkers will decline by 4% between 2019 and 2029. (indeed.com)

- If your lumber isn't as dry as you would like when you purchase it (over 22% in Glen Huey's opinion…probably over 10-15% in my opinion), then it's a good idea to let it acclimate to your workshop for a couple of weeks. (woodandshop.com)

- Woodworkers on the lower end of that spectrum, the bottom 10% to be exact, make roughly $24,000 a year, while the top 10% makes $108,000. (zippia.com)

External Links

How To

How to properly use your handsaw

Hand saws are used to cut the wood into pieces. Hand saws come in many forms, including circular saws. A hand saw is made from metal or plastic and cuts materials such as wood, plastics and metals.

A hand saw's main benefit is its ability make precise cuts at any angle, without the need to adjust it. They are also easy to sharpen, unlike power tools. However, there are some disadvantages as well. For example, they are heavy and bulky, so you must be careful when transporting them. If you are not familiar with how to use one you may injure yourself.

You can hold a handsaw in many ways. While cutting, it is important to keep your hands clear of the blades. If you don't, you might get hurt. You should hold the saw with your fingers close to the handle. Your thumb should be at the top of your blade. This will ensure that you don't accidentally touch or scratch the blade.

It is important to not put anything under the piece you are cutting when using a handheld saw. Doing so could cause the blade's surface to become uneven. Before cutting, be sure to check the area. Check for nails, screws and other objects underneath the wood.

Safety goggles should be worn when using a handsaw. They keep dust out of your eyes, making it easier for you see what you are doing. Safety glasses also protect your eyes from flying debris.

Before you start working with a saw, it is important to learn how to use it safely. Practice until you feel comfortable cutting. Once you've mastered the basics, you'll find that you can easily cut almost anything!